EPG manufacturer rotocultivator ploughshares in T. line have been chosen as the Nationwide Rotary Tillage Machinery Market “Excellent Brand Products” in 2007 by Rotocultivator Department of China Agricultural Machinery Market Affiliation.

Overview

Rapid Information

- Applicable Industries:

-

Production Plant

- Local Support Place:

-

None

- Surface Therapy:

-

Blacking, Sharpening, Anodization, Chrome Plating, Zinc Plating

- Year:

-

2014-2016, 2014-2015, 2010-2016ear:

- Tolerance:

-

Based mostly on drawingLength Dimension

- Standard:

-

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009

- Specification:

-

In accordance to the the drawing

- Warmth treatment:

-

Quenching & Tempering, Carburizing & Quenching

- product:

-

CT660, X-BOW

Supply Potential

- Offer Ability:

- 5000 Piece/Pieces for each Thirty day period

Packaging & Delivery

- Packaging Particulars

- Neutral paper packaging, wooden containers for outer box or according to customer’s demand.

- Port

- Shanghai / Ningbo

-

Guide Time

: -

Amount(Items) 1 – one thousand >1000 Est. Time(days) fifteen To be negotiated

On the internet Customization

We Ever-Energy Group with 4 branches more than 1200 staff is a single of the biggest transmission areas and machining things producers in China

Item Description

large quality cnc machining stainless metal propeller atv rear axle shaft

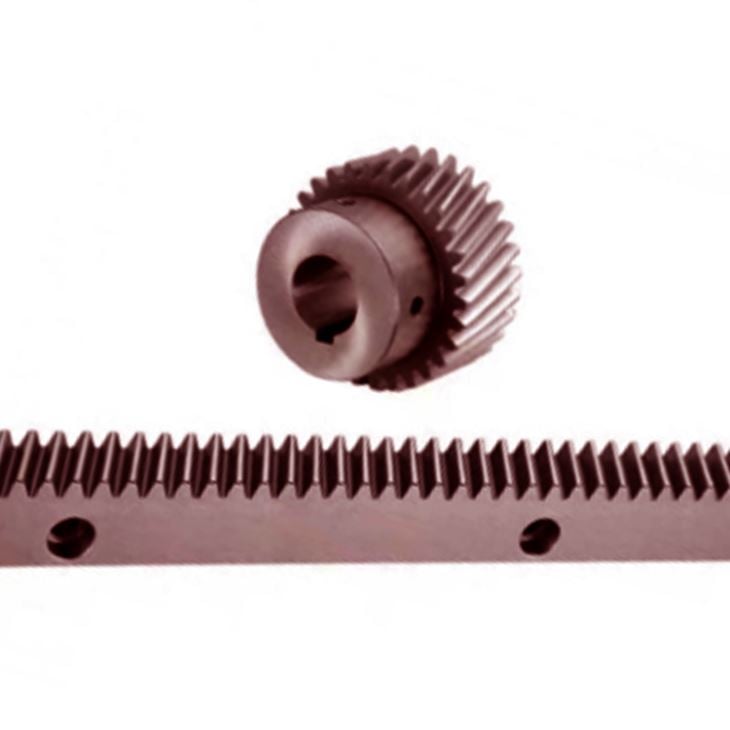

(one)All kinds of gears, shaft, gear shaft, precision gear and CNC gear.

(2)Specialised in manufacturing all kinds of automobile transmission element primarily based on Drawings.

(3)Materials: ductile solid iron, carbon steel, alloy steel , stainless steel, bronze/brass.

(four)Modules: M1 to M8 .

(five)Meets ISO, DIN and ASTM standards .

(6)Specification : In accordance to the the drawing.

|

Material |

Carbon Steel |

SAE1020, SAE1045, Cr12, 40Cr, Y15Pb, 1214Letc |

|

Alloy Steel |

20CrMnTi, 16MnCr5, 20CrMnMo, 41CrMo, 17CrNiMo5etc |

|

|

Brass/Bronze |

HPb59-1, H70, CuZn39Pb2, CuZn40Pb2, C38000, CuZn40etc |

|

|

Tolerance Control |

Outer Diameter |

Based on drawing |

|

Size Dimension |

Based on drawing |

|

|

Machining Method |

Equipment Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Equipment Lapping |

|

|

Tooth Precision |

DIN Class 4, ISO/GB Course four, AGMA Class 13, JIS Course |

|

|

Modules |

one., 1.25, one.5, 1.seventy five, two., 2.25, 2.5….8. etc |

|

|

Heat Therapy |

Quenching & Tempering, Carburizing & Quenching, Large-frequency Hardening, Carbonitriding |

|

|

Surface area Treatment |

Blacking, Sprucing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

|

|

Standard |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

|

Packaging & Delivery

EPG – 1 of the biggest electricity transmission elements, worm geared motors, agricultrual gearbox, planetary gear travel, helical,screw, beve gears and spare components and agricultural areas manunfacuter in China