A planetary gearbox is a primitive tool reincarnated in present day type, which says for itself regarding the usefulness and application of the device. It’s an efficient device for the function it performs and proved its relevant utility over time, with receiving no obsolete.

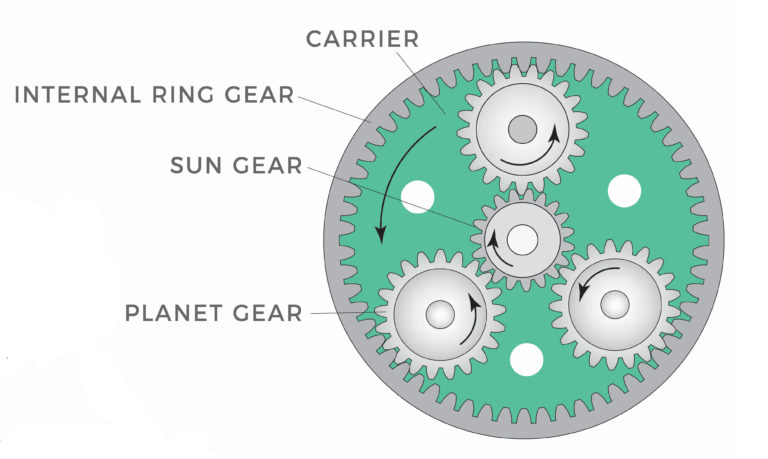

A planetary gearbox, also known as epicyclic gear box, comprises three types of gears — sun gear, planet gears and a ring gear and the gearbox has an input shaft aligned with the output shaft. The planet gears are mounted on a moveable carrier, and they rotate around the sun gear, which is positioned at the centre. The planet gears rotates around the sun gear and mesh with an outer ring gear. The three gears rotate in tandem within the planetary gearbox to make a stage. When required, more stage can be added to the gear system for higher ratios. The planetary gearbox’s basic function is to transfer the maximum quantity of torque with the least quantity of space. The process of the gear includes a reduction mode, an acceleration mode, and coupling.

Depending upon application, planetary gearboxes vary from very simple to intricate compound gear systems. Compound planetary gearboxes have significant plus such as higher torque to weight ratio, larger reduction ratio, and more flexible configuration.

How does a planetary gearbox work?

The principle of operation of a planetary gear structure differs from traditional parallel gears. Traditional gears rely on a few contact points between two gears to transfer the driving force. Thus, all the loading is concentrated on a few contacting surfaces, making the gears wear quickly and sometimes crack. But the planetary speed reducer has multiple gear contacting surfaces with a larger area that shares the load and can distribute the loading evenly around the central axis. Any instantaneous impact loading is also shared evenly, which makes them more resistant to damage from higher torque. The housing and bearing parts are also less prone to wear and tear from high loading as only the planet carrier bearings experience significant lateral force from the torque transmission and radial forces oppose one another and are balanced, and axial forces only arise when using helical gears.

In a typical planetary gearbox, the input shaft is connected to the sun-gear. The planet-gears, which are mounted on a moveable carrier and assembled within the external ring gear, are thus driven by the sun-gear, forming the output shaft to drive the load connected to it. The external ring gear has a fixed position in relation to the outside world. The entire set of the planetary gear system revolves on its own axis.

In simple sentence we can say, the sun gear is connected to the input shaft, the carrier mounted plane gears are connected to the output shaft and the external ring gear is the housing.

Where are planetary gearbox used?

Planetary gearboxes are mostly used when space and weight are a constraint, but an outsized amount of speed reduction and torque are needed. This requirement applies to a spread of industries, including tractors and construction equipment, where an outsized amount of torque is required to drive the wheels. Planetary gearboxes are also found in other applications such as turbine engine, automatic transmissions and electric screwdrivers. Some key area of application of planetary gearboxes are:

- For precise positioning in axis drive for laser cutting machines and 3D printers

- Wheel hub drive of automatic guided vehicles (AGV)

- In a robot to increase the torque

- Height adjustment of operating tables

- In a print press to scale back the speed of the rollers

- In the wheel hub drive of heavy vehicles and construction equipments

Features of planetary gearbox:

Advantages :

Planetary gearboxes can supply tons of speed reduction and torque inside a small package and have operating characteristics beyond those of fixed-axis gear systems. The primary advantages of planetary gearboxes are:

- Planetary gearboxes are compact and low weight — as much as 50% reduction in size and weight compared to traditional gearboxes with same torque output.

- Increased repeatability — Their radial and axial motion of load offers greater reliability and robustness, reducing the misalignment of the gear. They offer uniform transmission with low vibrations at different loads, which provide a perfect repeatability.

- High torque density — Because of several planets sharing the load rather than one gear, they offer high power density. Increasing number of planets will increase the torque density.

- Perfect precision — Due to rotating angular stability, gearing can be very accurate with virtually no backlash, and the movement can be reliable.

- High efficiency — Due to their design and internal layout, losses are minimized during their work and hence offer greater efficiency.

- Greater durability — Greater efficiency and much smoother operation can be achieved by using bearings which can help reduce the torsional rigidity and improve rolling.

- Because of coaxial arrangement, no offset output shaft is required.

- Maximum versatility: Modular, which can be installed in almost any space. Most planetary stages can be stacked.

Disadvantages:

- Noisier Operation — Sometimes due to design constraint some planetary gearboxes are noisy.

- The sun gear, planet gear and ring gear must be accurate and balanced to assure load sharing.

- Sometimes high bearing loads can lead to early wear in the gear system.

- The compact design of planetary gearboxes make heat dissipation more difficult, so system that run at very high speed or continuously function may require cooling.

- Oil bath is better than grease lubrication.

- When using multiple stages, gearboxes get very long because of high ratio of length to diameter.

Cost somewhat increases if low backlash and long life is required.

Why are planetary gears stronger than other gear combinations, and how do a planetary gearbox increase torque?

Planetary gear systems are stronger and produce a lot of torque because the load in this gear system is shared by multiple planet gears. The load ability and torque density increases with the number of planet gears in the system. This gear system creates larger contact area and more contact surface between the gears, which enables even load mass distribution and increased rotational stiffness. Because of this, it has superior stability and therefore the gear system is more resistant to damage.

What causes planetary gearbox failure?

Despite advantages like compactness and high torque to weight ratio, like any other machine the planetary gearbox also breaks down before rated life under severe conditions such as improper installation, misalignment, overloading, over speeding, improper lubrication or use of wrong grade lubrication, wrong bearing selection. Some of the common failures observed in the planetary gearbox are mentioned below:

- Abnormal noise and vibrations in planetary gearbox.

- Gear teeth worn out

- Temperature at gearbox

- Breakdown of output shaft

- Locking of gearbox shafts

WHY A PLANETARY GEARBOX FROM china Gearboxes

Cases of successful implementation of planetary gear units in China Gearboxes