Worm Gearbox for Thermal Power Plants

Our worm gearbox is a high-performance, industrial-grade device designed specifically for thermal power plants. It exhibits exceptional power transmission capabilities, durability, and energy efficiency, making it an integral component in energy production.

Features of Our Worm Gearbox

- Robust Construction: The gearbox is built with high-quality materials to withstand heavy-duty operations.

- High Efficiency: Its innovative design guarantees optimal power transmission with minimal energy loss.

- Long-lasting Performance: Our worm gearbox offers prolonged service life with minimal maintenance required.

- Easy Installation: The compact and versatile design of the gearbox enables easy installation in any setup.

- Reduced Noise Levels: The smooth operation of our gearbox ensures reduced noise and vibration.

Applications of Worm Gearbox in Thermal Power Plants

- Power Generation: Our worm gearbox is suitable for varying operational requirements in power generation.

- Energy Efficiency: The gearbox’s high efficiency contributes to reduced energy consumption and operational costs.

- Heavy-Duty Operations: The robust construction makes it ideal for heavy-duty operations in thermal power plants.

- Space Optimization: Its compact design allows for optimal use of space in power generation units.

- Reliability: The long-lasting performance of our gearbox ensures uninterrupted power production.

Working Principle of Worm Gear Motor

The worm gear motor operates on the principle of speed reduction where a high-speed input from the worm, or screw gear, is transformed into a low-speed, high-torque output by the worm wheel.

Choosing the Right Worm Gear Reducer

- Power Requirements: Consider the power requirements of your thermal power plant to select the right gearbox model.

- Operational Load: The gearbox must be capable of handling the operational load without failure.

- Size and Mounting: Choose a gearbox that fits your space and mounting requirements.

- Maintenance Needs: Opt for a gearbox that requires minimal maintenance for hassle-free operation.

- Cost-effectiveness: Consider the total cost of ownership, including purchase, installation, and maintenance costs.

Motors for Worm Gear Reducers

Our worm gear reducers work hand-in-hand with electric motors to deliver exceptional performance in thermal power plants. We also offer a wide range of electric motors designed to work perfectly with our gearboxes.

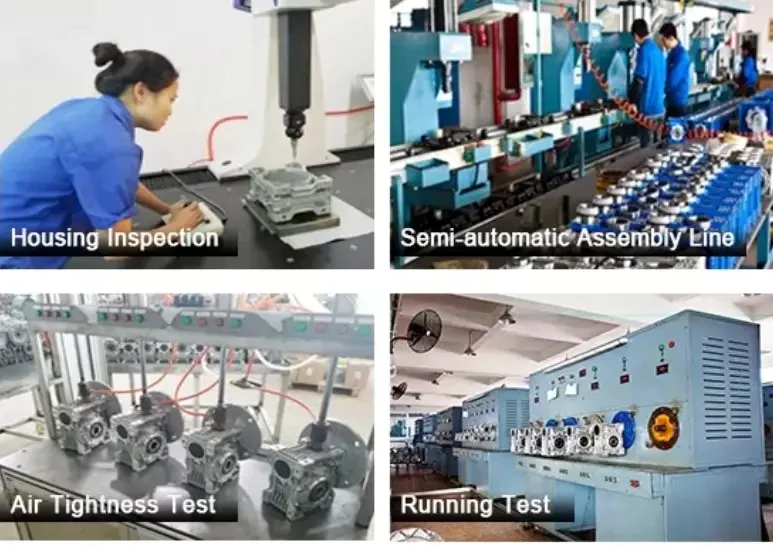

About Xinlan Gearbox Manufacturer

We are a comprehensive transmission equipment manufacturer with over 15 years of experience serving global customers. We offer high-quality, energy-efficient, and stable gearboxes at competitive prices. Our worm gearbox for thermal power plants is widely used and praised in the industry. Explore our product range and contact us for your gearbox needs.

FAQs

Q1: What is the warranty period for the worm gearbox?

A: We offer a 1-year warranty for our worm gearbox.

Q2: Can I customize my worm gearbox?

A: Yes, we offer customized solutions to meet your specific requirements.

Q3: How do I maintain my worm gearbox?

A: Regular inspection and timely lubrication can ensure the long-lasting performance of our worm gearbox.

Edited by Zqq.