Worm Gearbox for Vacuum Forming Machines: An Overview

Worm gearboxes, also known as worm gear reducers, are an integral part of vacuum forming machines. These devices are designed to reduce rotational speed while increasing torque, providing efficient power transmission. Known for their compact design, durability, and high load capacity, worm gearboxes are perfectly suited for vacuum forming applications.

Key Features of Worm Gearboxes

- High torque output: Worm gearboxes are known for their ability to generate high torque, which is essential for vacuum forming machines.

- Compact design: These gearboxes are compact and easy to install, making them suitable for machines with space constraints.

- Durability: Made from high-quality materials, worm gearboxes are designed to withstand harsh operating conditions.

- Low noise operation: Worm gearboxes operate quietly, contributing to a more comfortable working environment.

- Efficiency: With a high gear ratio, these gearboxes ensure efficient power transmission, resulting in better machine performance.

Applications of Worm Gearboxes in Vacuum Forming

- Efficient power transmission: Worm gearboxes ensure efficient power transmission, making them ideal for vacuum forming machines.

- High load capacity: These gearboxes can handle high loads, making them suitable for heavy-duty applications.

- Compact design: Their compact design makes them ideal for applications with space constraints.

- Durability: The durability of worm gearboxes makes them suitable for long-term use in vacuum forming machines.

- Quiet operation: The quiet operation of these gearboxes contributes to a comfortable working environment.

Working Principle of Worm Gear Motor

The worm gear motor works by converting the rotational motion of the motor into linear motion. This is achieved through the interaction of the worm (a screw-like component) and the worm gear (a toothed wheel). The turning of the worm drives the worm gear, resulting in a change in the direction of the power transmission and a decrease in speed. This process increases the torque, making the worm gear motor ideal for applications requiring high torque and low speed, such as vacuum forming machines.

Choosing the Right Worm Gear Reducer

- Consider the load requirements of your application. Choose a worm gear reducer that can handle the load without overheating or failing.

- Consider the space available for installation. If space is limited, choose a compact worm gear reducer.

- Consider the operating conditions. If the gearbox will be exposed to harsh conditions, choose a model made from durable materials.

- Consider the speed requirements of your application. Choose a worm gear reducer with an appropriate gear ratio to achieve the desired speed.

- Consider the noise level. If a quiet operation is important, choose a worm gear reducer designed for low noise operation.

Motors for Worm Gear Reducers

Worm gear reducers and motors go hand in hand. The motor provides the initial rotational motion, which the reducer then modifies to suit the requirements of the application. Both components are crucial for the efficient operation of vacuum forming machines. We also offer a range of electric motors specifically designed to work with our worm gear reducers.

About Xinlan

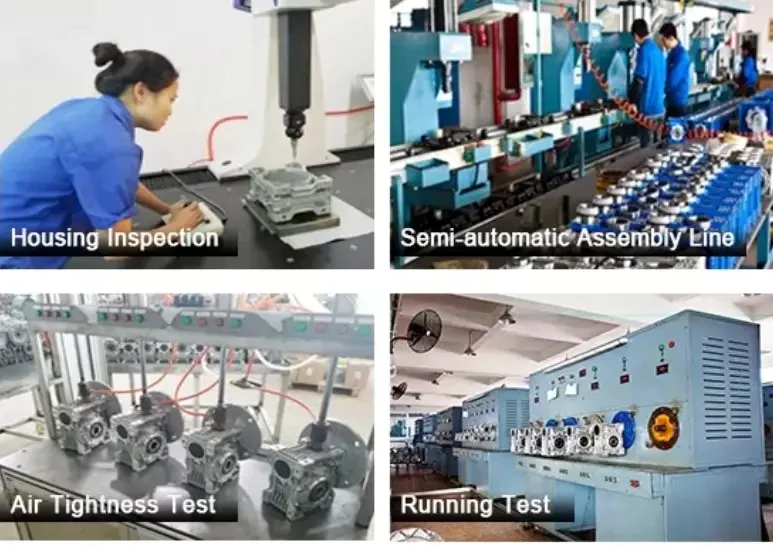

With over 15 years of experience in the industry, Xinlan is a leading manufacturer of speed reducers, including worm gear reducers. Serving customers in Europe, America, Africa, Asia and more, our products are highly regarded for their quality, efficiency, and stability. We employ innovative research and development strategies and use advanced production and testing equipment to ensure the highest standards in our products. Our main products include various types of worm gear reducers, widely used in several industries.

We invite you to explore our range of worm gear reducers for vacuum forming machines and contact us for purchasing inquiries. We provide the best service, the highest product quality, and the most competitive prices in the market.

Q&A

- Q: Can I use a worm gearbox for my vacuum forming machine?

- A: Yes, worm gearboxes are ideal for vacuum forming machines due to their high torque output and efficient power transmission.

- Q: How do I choose the right worm gearbox?

- A: Consider factors like load requirements, available space, operating conditions, speed requirements, and noise level to choose the right worm gearbox.

- Q: Does Xinlan offer electric motors for worm gear reducers?

- A: Yes, we offer a range of electric motors specifically designed to work with our worm gear reducers.

Edited by Zqq.